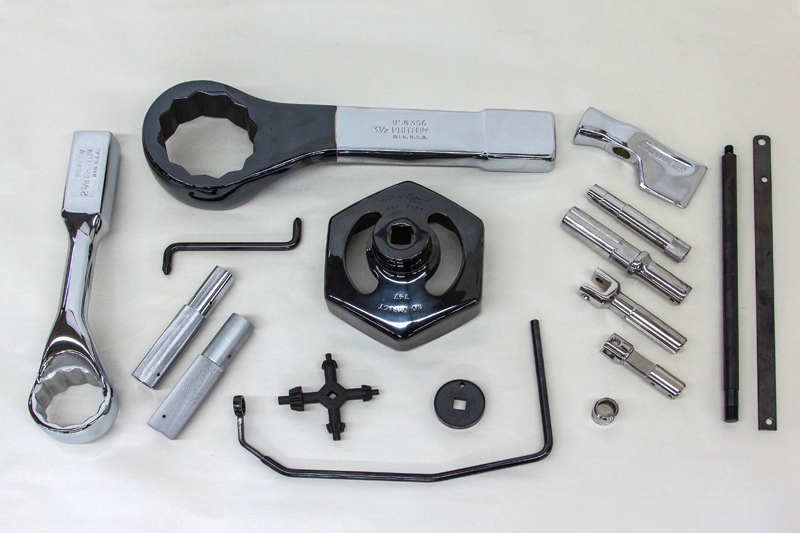

Chrome & Black Oide Plating of Tooling Components

One type of product you would likely see in our shop on any given day is a tool component. At Pentrate Metal Processing, and California Electroplating, Inc., we are a major provider of plating services to a large international tool manufacturer. For the past 30 years, we have been chrome plating torque wrench components using a highly refined process. By combining automated process controls with constant monitoring and analysis of bath chemistries, we produce a high quality chrome finish accurately and consistently on each lot. Our technically trained staff, some of who have been with us for more than 30 years, has developed a racking method that allows us to optimize part density. This space utilization results in excellent throughput rates by maximizing the number of parts that can be processed in each batch. With this type of production efficiency, we are able to keep costs at a very favorable level while maintaining the superior quality chrome finish the client expects.

In addition to chrome plating, we also apply both black oxide and phosphate coatings to tools and tool components. We run these finishes either on racks or in barrels. Our custom designed plating barrels allow us to process many different parts that were previously racked, saving significant plating expense.

Another way we keep plating costs low is to suggest design changes that facilitate the plating process. Correct positioning of racking holes, adding airways in recessed areas, and creating drain holes are just three examples of how small modifications can improve the flow and drainage of the process solution to decrease cycle times and production expense.

Contact us today to learn more about our plating and finishing capabilities.