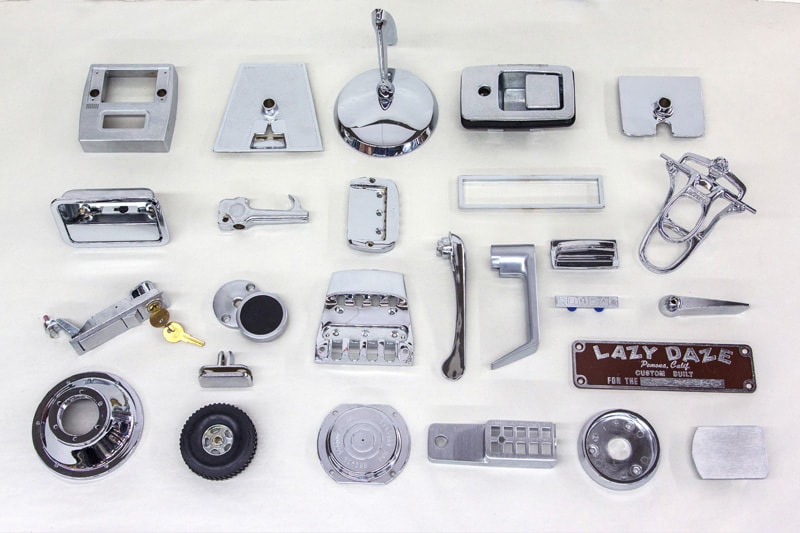

Chrome & Nickel Plating of Die Cast Zinc Parts

At California Electroplating, Inc., chrome and nickel plating of zinc die cast components is one of our specialties. We have a lot of experience with zinc die cast parts and produce finishes that are durable as well as rich in appearance. Our plating business was founded in 1915, and by consistently staying up-to-date on the latest in plating techniques and process technology, we have maintained a leadership position in the industry.

We have developed a proprietary process specifically geared for handling zinc die cast parts. In addition to an automated processing line for high volume orders, we operate a manually controlled production line for processing small and specialty custom orders. Both of these processing lines are run by skilled operators who handle each job with the utmost care and precision.

Our multi-step process for all zinc die cast parts begins with a thorough cleaning and neutralizing to optimize the surface for the plating process. Parts then receive a copper underlayment to promote uniform adhesion of the nickel or chrome. We produce both satin and bright finishes in nickel, and both trivalent chrome and hexavalent chrome are offered as options.

For high-end applications, we use a heavy copper underlayer that is buffed to a mirror-like shine prior to plating it with chrome. This results in a superior quality finish with an impressive appearance and outstanding durability.

To learn more about how our plating processes can add durability and luster to your zinc die cast parts, contact us directly.